Several corrosion resistant stainless steels have been developed specifically with the aim of solving corrosion problems within the pulp and paper industry. This knowledge guide walks you through the best stainless steels to employ in different process areas.

Strong, economical and sustainable

Duplex stainless steels have been at the forefront of performance in the pulp & paper industry since their introduction by Outokumpu in the 1930’s. Thanks to their high mechanical strength, the duplex stainless steel family can deliver customers considerable material weight and cost savings. All duplex grades can also be produced using cost-effective lean alloying processes which ensure accurate budget calculation for large-scale investment projects.

The corrosion performance of duplex stainless steels makes them perfect for the hot alkaline, acidic and water environments most often associated with the pulp and paper industry. This is a key in ensuring a long service life – and just like all stainless steels, duplexes are fully recyclable during the decomissioning stage.

Top benefits of choosing Outokumpu stainless steel for pulp and paper industry

Applications

- Pulp mills

- Pressure vessels

- Processing and storage tanks

- Hot alkaline environments

- Acidic chlorine environments

- Hot water and chlorides

Performance

- High mechanical strength

- Service temperature range from -40⁰C up to +250⁰C

- Excellent corrosion resistance in typical pulp & paper environments

- Easy to weld

- Wide range of products available from 0.4 mm cold rolled up to 100 mm quarto plate

- Material weight and cost savings

- Investment cost stability and predictability

- Good availability enables use of optimal grade for each application

- Low maintenance, long and reliable service life

- Fully recyclable

Pulp & Paper

Stainless steel grades for corrosive environments

Hot alkaline environment

In the alkaline environment of pulp mills, uniform corrosion is the typical corrosion mechanism. Laboratory tests and industry experience have shown that lean duplex grades Forta EDX 2304 perform well in these conditions. Surprisingly the “acid proof” molybdenum alloyed stainless steel grades like 316L suffer from rapid deterioration. In addition, duplex grades show superior stress corrosion cracking resistance in alkaline environment compared to 304L.

Acidic chlorine environment

In an acidic chlorine environment, the key to enhancing the corrosion resistance of stainless steel is the introduction of increased chromium, molybdenum and nitrogen content. With that in mind, austenitic high-alloyed grades like Ultra 254 SMO and Ultra 904L are well suited to the conditions, with duplex grades Forta SDX 2507 and Forta DX 2205 also exhibiting similar corrosion resistance combined with high mechanical strength and leaner alloying of volatile elements. In all cases, performance can be assessed with the help of PREN (Pitting Resistance Equivalent) and CPT (Critical Pitting Temperature) values.

Hot water and chlorides

Typical austenitic stainless steels such as 304L and 316L are susceptible to stress corrosion cracking due to warm, chloride-heavy environments – generally at temperatures above 50°C. High-alloyed austenitic Ultra grades however show much better performance and Duplex stainless steels, thanks to their austenitic-ferritic microstructure, are extremely resistant in these conditions. The stainless steel grade selection depends on the conditions and can vary from the leanest – Forta LDX 2101, right up to Forta SDX 2507.

Weight saving and cost predictability with duplex solution

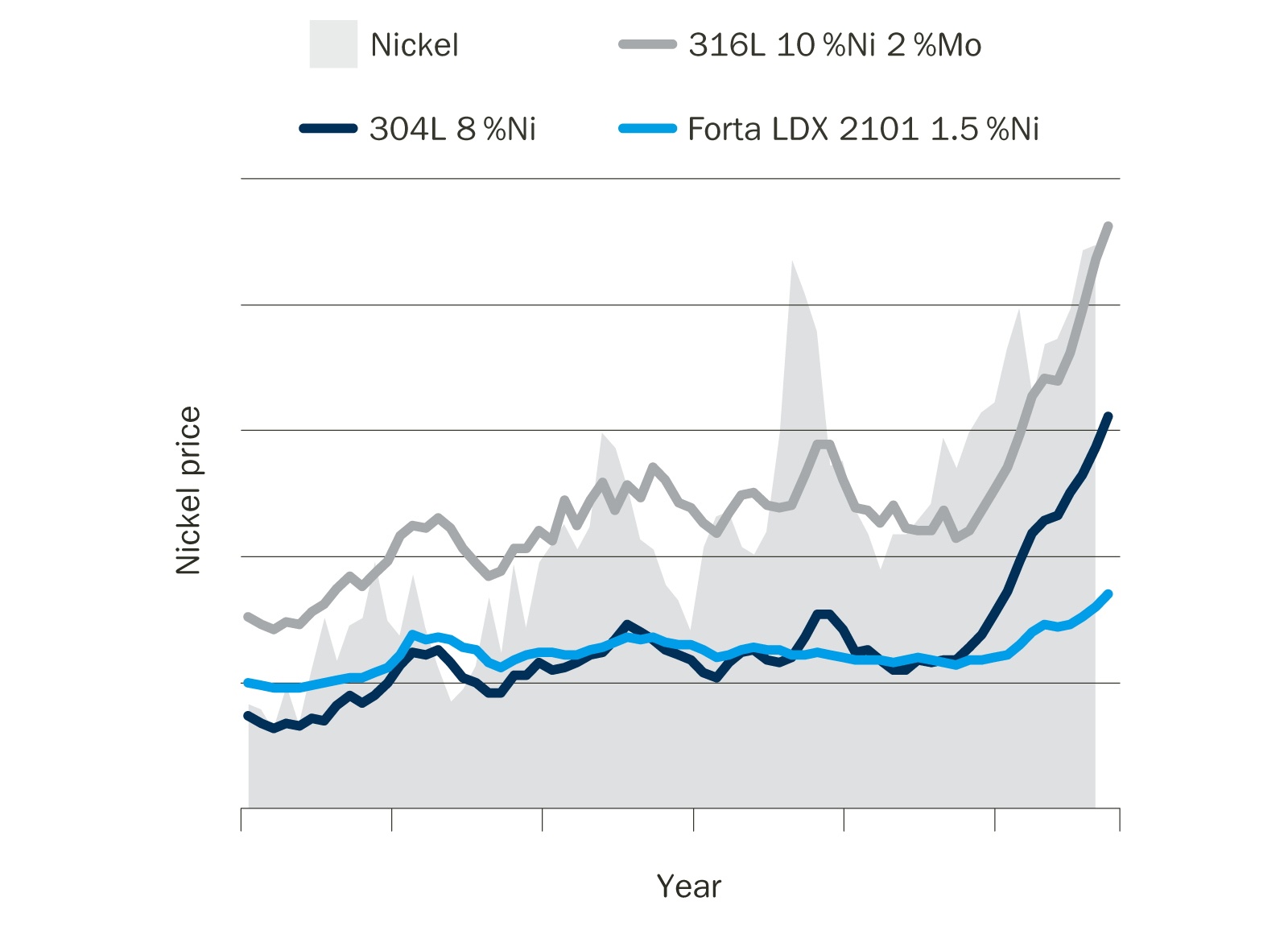

Compared to austenitic grades, duplex stainless steels are generally lean with volatile and expensive alloying elements such as nickel and molydbenum. Forta LDX 2101 lean duplex is an extreme example of this: It's corrosion resistance is achieved mainly by the alloying of chromium and nitrogen, while it's nickel content is only 1.5%. Duplex grades have high mechanical strength, which enables considerable weight savings in pulp & paper industry applications – such as pressure vessels and various types of processing and storage tanks. As such, duplex grades make for optimal construction materials for capital investment projects that require cost predicatability.

Figure: Lean duplex provides superior price predictability over 304L and 316L due to its lean alloying concept.

Read the article: Achieving material cost predictability in the pulp and paper industry with lean duplex stainless steel

Sustainable solution

When it comes to the use of recycled material stainless steel production, Outokumpu is the world leader, with an average of over 90% recycled material used in manufacturing. We're also leading the change towards more sustainable production, with the lowest carbon footprint in the global stainless steel industry.

Thanks to exceptional corrosion resistance, products manufactured using duplex stainless steels enjoy long and low maintenance service lives, making them the sustainable choice for production. Futher – all duplex grades are also fully recyclable upon decomissioning, contributing to a cycle of sustainable material reuse.